About.

WHO WE ARE. WHAT WE DO.

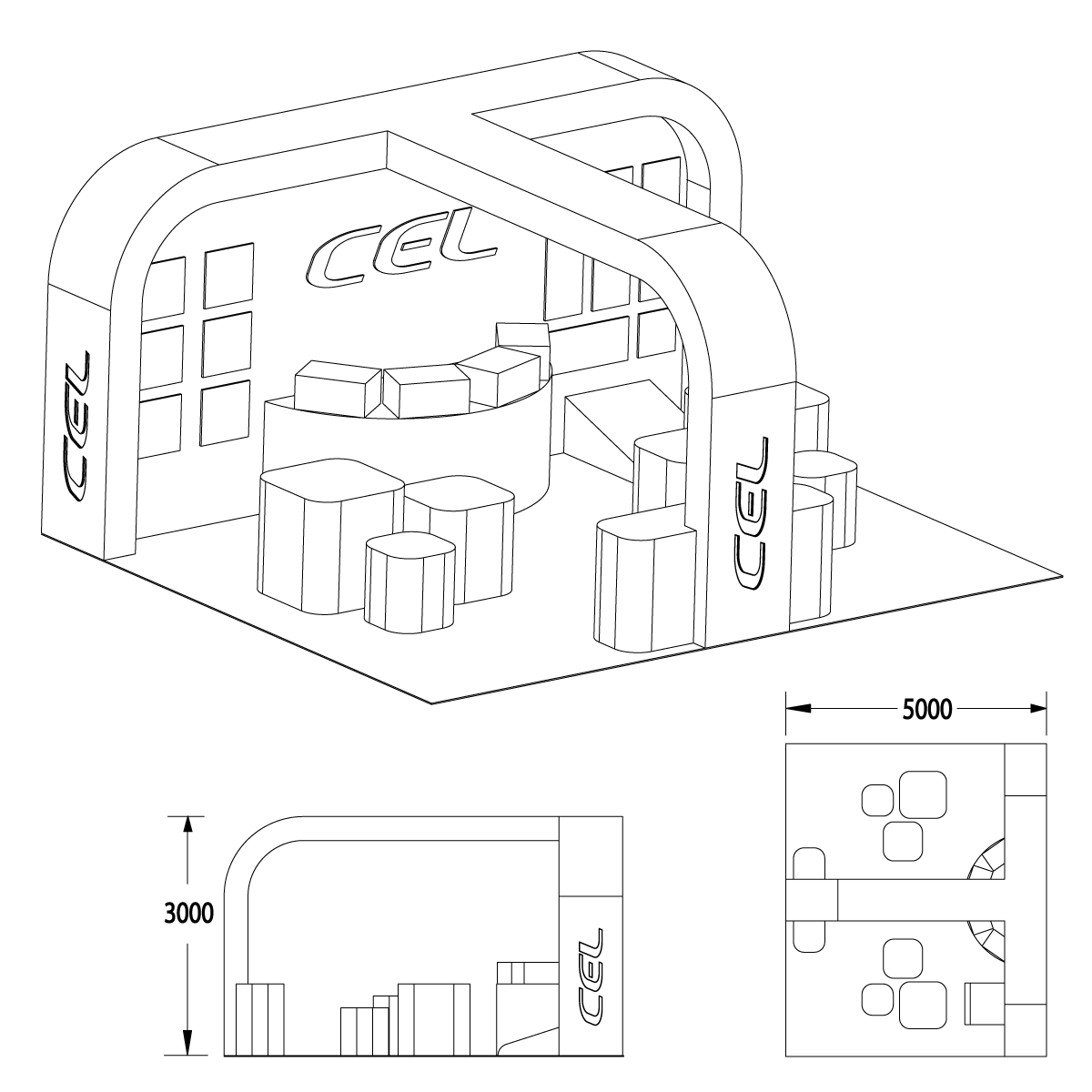

Based in Portishead near Bristol in the heart of the South West, we offer high quality engineering and design consultancy and services including CNC machining, routing, 3D printing, vinyl/die cutting, plotting, drilling and fabrication.

Our design engineering team has over 20 years’ experience taking products from idea to reality and all the way through production to local and global markets. If your idea is a prototype of a product or a bespoke piece of art we can help with every stage from design, through prototyping to manufacture and provide advice on procurement and logistics to ensure the final delivery is the best it can be. We really can provide everything you need.

We love ideas. We love design. We would love to talk to you about your ideas and how together we can bring them to life.

We started in a garage. Chris the CEO is a product design engineer and has lead the company from this humble space in his family home to become a growing local employer and the family ethos has stuck throughout, all of us here are very approachable and ready to take the extra steps to get any job done.

Contact us using the form on this page or call the number below. If you want to pop in and see what we do and how we do it or just to talk through your method please let us know so we can put the kettle on (and sweep the floor).

Work.

RECENT PROJECTS.

Capabilities.

HOW WE CAN HELP.

We provide a wide range of services from our production facility in Portishead. If you need any advice, just give us a call.

TIMBER CNC SERVICES.

CUTTING AND POCKETING

We can cut any 2D design including pockets of varying depth and this forms the majority of the work we do. The accuracy of CNC control combined with a high quality motion system allows us to produce incredibly detailed designs with a typical tolerance of 0.2mm in the majority of materials.

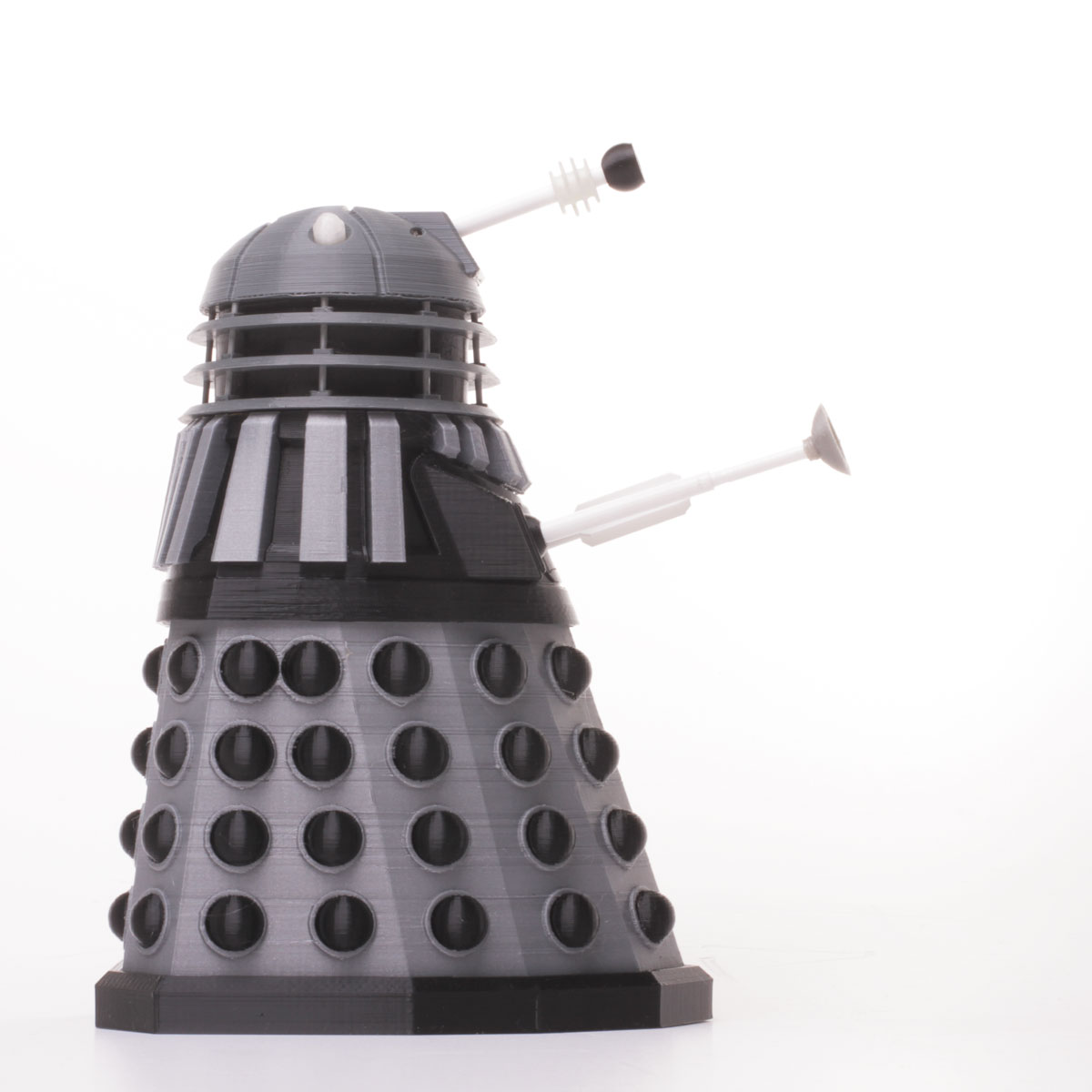

3D PRINTING

Using our in-house 3D printers, designed by us, we can produce any component up to a maximum size of 300 x 210 x 400mm (LxWxH) from a variety of materials including ABS, PLA, PETG, CO-PET, PC, HIPS, PA6, PA12, PA-CF, PA-GF, TPU, PVOH, PolyWood™ and PolySupport™. Our machines use the FFF/FDM process to produce parts from a variety of thermoplastics and can achieve dimensional tolerances of ±0.1mm. There are a huge range of possible applications including prototyping, models, jigs and fixtures, spare parts and short-run customised manufacturing. Contact us to find out how 3D printing could help your business.

3D MILLING

Using our 3-axis machine we can also create full 3D geometry for relief carvings, contoured and textured surfaces. This is a more complex process which requires more machine programming, so extra cost may be involved to prepare the drawings.

VINYL/DIE-CUTTING AND PLOTTING

Using our CNC controlled die-cutter/plotter, we can produce any design from a wide variety of materials including self-adhesive vinyl, paper and card as well as sketching and plotting using any pen. We can produce artwork of an unlimited length upto a maximum width of 720mm (28″). Create an impact with custom logos and branding including wraps – get in touch to talk to us about your project.

DRILLING AND COUNTERSINKS

We can produce any design, piercing an entire sheet or just specific locations, as well as inserting countersinks where required.

MOULDING

We can add any design of edging or moulding to the sides of your parts for a more traditional finish e.g. softening radii, ogee profiles and chamfers – if there’s a cutter available, we can cut it!

ENGRAVING

Using modified tooling we can produce very complex designs to a high level of accuracy in a variety of finishes. As an alternative to laser cutting/engraving, routing can produce a cleaner finish with less post-processing for scorch marks.

POST-PROCESSING

We can provide a variety of other services alongside the above including sanding and finishing, painting, laminates and edge-banding. We can also perform folding operations in certain materials, for example aluminium composite panels. Contact us to discuss your project requirements.

DESIGN SERVICES

If you need help generating your design or producing CAD geometry, we can help. We usually aid with preparing drawings for cutting, but we can also provide bespoke designs if necessary. We charge a minimum of £40 exc. VAT for this service, but it’s always best to contact us to discuss your ideas and get an indication of the costs involved.

PACKAGING AND DELIVERY

We understand the importance of receiving your parts in perfect condition, and we have preferable rates with a number of couriers. We can offer same day, next day and timed deliveries, or alternatively you are welcome to visit our workshop in Portishead to collect. If you have any particular packaging or shipping requirements, please let us know in your enquiry – our standard quoting includes next day delivery.

METAL AND PLASTIC CNC CAPABILITIES.

4, 5 & 6 AXIS CNC

We can create complex 3D shapes in all rigid materials using a range of precision machinery.

2D & 3D MILLING AND MACHINING

Combined Turning and Milling including mill-turn and multi-spindle operations.

We offer a fast and exact CNC turning service for parts which can be created around a single axis. Our machinery can include milling operations for additional features.

Our CNC milling machines can create high accuracy irregular shapes and are ideal for fixtures and components. Mill-turn allows us to include features on several planes.

We are capable of fulfilling manual and automated CNC machining for small or very large quantities.

EDM, PLASMA, LASER & WATERJET CUTTING

EDM Spark Erosion, Plasma, Laser and Waterjet cutting services allow us to process specialist materials which challenge the cutting capabilities or capacity of other machinery.

We would be very happy to discuss your requirements and advise on the best approach.

PRESSED, CAST AND FORGED PARTS

Press braking, folding and forming services provide panels and structure using low cost processes and materials with big volume benefits.

Cast and Forged parts are excellent for volume production or where blanks or billet metals are not suitable or cost effective. Combining these methods with CNC and other services allows incredible flexibility while retaining accuracy and reduced cost.

Our services will help you to generate and test these production methods to ensure they are suitable for your needs.

ADDITIONAL SERVICES

We can also create and refine parts using methods which include or compliment CNC machining:

- Tapping

- Routing

- Polishing

- Grinding

- Deburring

- Hone and Lapp

- Engraving

FINISHING

CNC operations leave marks around the tool path. Often these are desirable as evidence of the process and craft but there are many options for finishing for durability or cosmetic reasons.

- Anodising

- Shot and bead blasting

- Post process engraving and texturing

- Erosion

- Plating such as Chrome or Nickel

- Painting and Powder Coating

Masking is available for many of these operations to create a combined appearance.

MATERIALS FOR MACHINING

To limit the materials we can process to this list would be incorrect. A greater challenge may increase cost but we only advance in this way.

Plate, sheet, block or rod

- Titanium

- Aluminium

- Brass

- Copper

- Stainless Steel

- Nitronics

- Duplex

- Inconel

- Maraging Steel

- Mild Steel

- Steel

- Carbon Steel

- Phosphor Bronze

- Aluminium Bronze

- Nickel Alloys

Any rigid plastic

- ABS

- Delrin

- Nylon

- Polycarbonate

- Acrylic

- Polyproylene

- Polystyrene

- PTFE

- UHMW

- PEEK

- PAEK

- Urethane

- Tufnol

- Most composites

INJECTION MOULDING CAPABILITIES

TOOLING AT ANY SCALE

When there is sufficient volume injection moulding is unbeatable on a price per item basis.

The upfront cost of high quality tooling can push a project toward other methods and this is certainly true for parts which require large tooling. Upfront investment can be very high. We are experts in reducing this cost.

For smaller parts the volume requirement can be surprisingly low and we recommend exploring this type of manufacturing before going in another direction.

Our experience in tooling design for manufacture spans 20 years and hundreds of products. Many of these tools have produced tens of thousands of products and are still going strong today.

If you need a custom foot or button for your workshop equipment or a housing for your precision dental equipment we can help. Consultation or full service from design to delivery. We can step in at any stage or lead you through the whole process.

ELECTRONICS, PCB AND MOTION CONTROL DEVELOPMENT

FROM 16 AXIS PROFILED MOTION MACHINERY TO SIMPLE UX FEEDBACK DEVICES

Electronics and underlying code define the actions and response of all the powered devices we use today. It is rare for new technology to be compatible with off shelf devices, we can offer full consultancy on custom system design and alternatives with all the limitations and costs.

Our primary electronic expertise is in motion systems but before this we have created thousands of small devices to provide control or respond to user input in power tools, household electrical items and personal vehicles.

Advanced motion control systems which we have developed allow familiar g-code motion paths to be accurately processed with full feedback and automated control. High power stepper motor and servo control is combined with high speed communication with remote daughter boards. This gives immense expandability and control over multiple sensors and end effectors.

- Reliable electronics for any environment or purpose large or small volume with fast development.

- Simple sensor, control or interface electronics for battery or mains powered products.

- Customised and specific electronics and firmware for specialist devices.

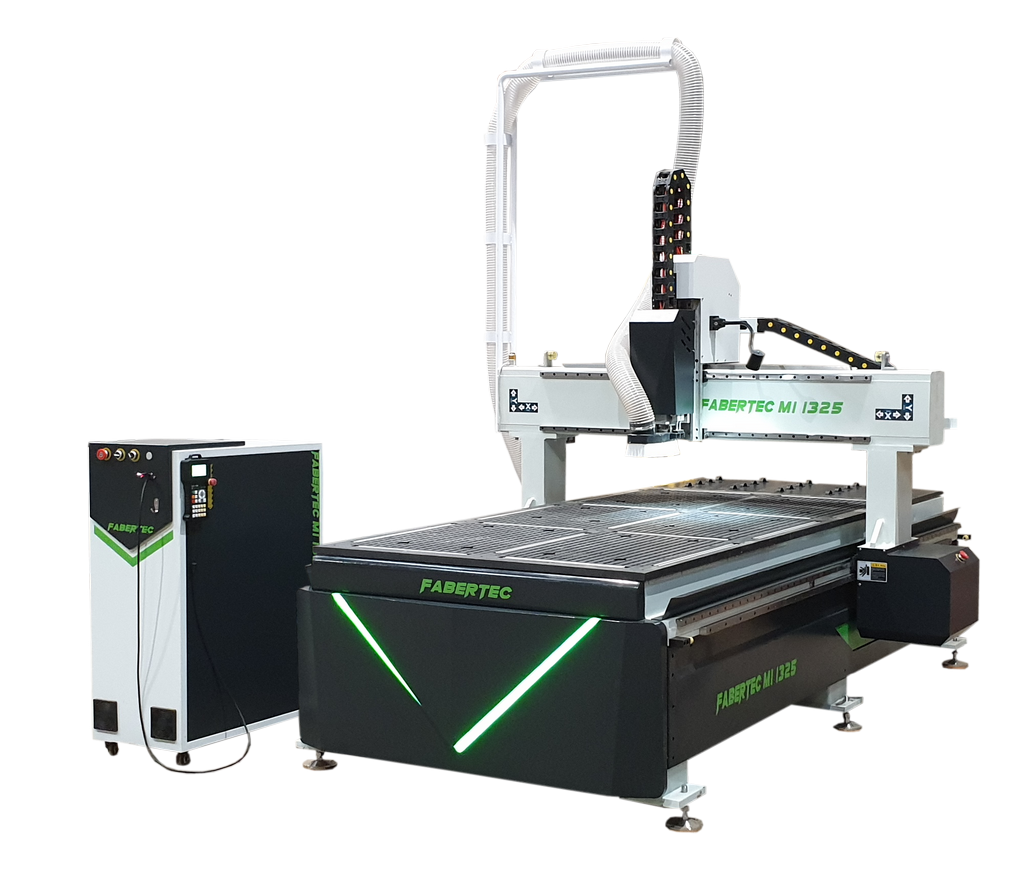

Equipment.

WHAT WE CAN DO.

Our growing selection of CNC Routers allows us to produce final cut shapes from a variety of sheet materials.

In-house machining on our 2.5 x 1.3m CNC Router, specifications below:

CUTTING/ROUTING

- Working Area: 1300mm x 2500mm

- Max Working Height: Axis Z300 mm

- Motors: Servo 750W

- Linear Bearings: Trapezoidal Tracks

- Speed: 40 m/min

- Software Resolution: 0,01mm

- Positioning Accuracy: physical 0,05 mm

- X Gate Double Motors: Yes

- Spindle: HSD 6kW

- Spindle RPMU: up to 18000 RPM

- Brushless Spindle: Yes

- Collet Size: ER32

- Router Bed: Vacuum bed with pump hybrid with T slot

- Weight: 900 kg

- External Dimensions: 2000mm x 2350 mm

- Power Supply: 400 V 3 Phase

- Control Software: Vectric V-Carve Pro

- Supported File Formats: .dwg, .dxf, .eps, .ai, .pdf, .bmp, .jpg, .png

- Working Area: 1300 x 2500mm

- Resolution Accuracy: 0.01/100mm

- Spindle Power (Water-cooled): 4.5kW

- Spindle Speed: 0-24,000rpm

- Gantry Height: 180mm

- Collet Size: ER 25

- Fixturing: 4-Zone Vacuum Bed and T-Slot Table

- Control Software: Vectric V-Carve Pro

- Supported File Formats: .dwg, .dxf, .eps, .ai, .pdf, .bmp, .jpg, .png

AVAILABLE MATERIALS FOR ROUTING

- Hard and Softwood Plywoods – variety of veneers/laminates available

- Medium Density Fibreboard (MDF) – standard, fireboard and exterior-use variants

- Oriented Strand Board (OSB)

- Aluminium Composite Panel e.g. DiBond® – variety of finishes and colours available

- Aluminium 1050 Sheet

- Acrylic (Cast and Extruded) – variety of finishes and colours

- Polycarbonate – variety of finishes and colours

- And more! – Get in touch if there’s something not listed…

MULTI-AXIS CNC MACHINING

Our machining services reside within our own partner factories where they are used to produce tooling and components for high quality consumer products. We can offer simple part quoting as a service with very fast lead-times or include our own design engineering service to optimise designs and methods.

These facilities are constantly updating and have very high capacity even when extremely high tolerance is required.

These new services gives access to precision CNC machining in metal and specialist plastics and also injection moulding which would not usually be available to the public at these prices. Please allow us to surprise you with a very competitive quote.

Automation Development Hardware

CNC / Additive Manufacture

This development platform combines additive manufacture and a 5-axis milling machine to produce a machine with unprecedented flexibility and power. We can:

- Print directly onto an existing component ideal for composites and flexible production

- Print much faster. A base part or form can be used and support structures are no longer required

- More complex geometry with unlimited lamination direction for big weight savings or unique flexibility

- Smoother curved surfaces, Stronger parts and Less waste

Incorporation of wiring

Within these parts we can spool common specification wiring directly into the piece as it is printing, this provides:

- Lighter components which can contain complex 3D wiring

- Higher quality, Lower cost, Shorter development time and More robust pieces with the reliable conformity of automation

3D component positioning

Wiring placed in a structure enables us automate the addition of connectors, electronics and other components. This makes it possible to:

- Create complete assemblies and Seamlessly incorporate production into manufacturing

- Completely automate the production with immense control from CAD and simulation to final part in an unbroken manufacturing loop

Our subcontracting services for grant and R&D work are flexible and transparent. We would be very happy to assist with any application.

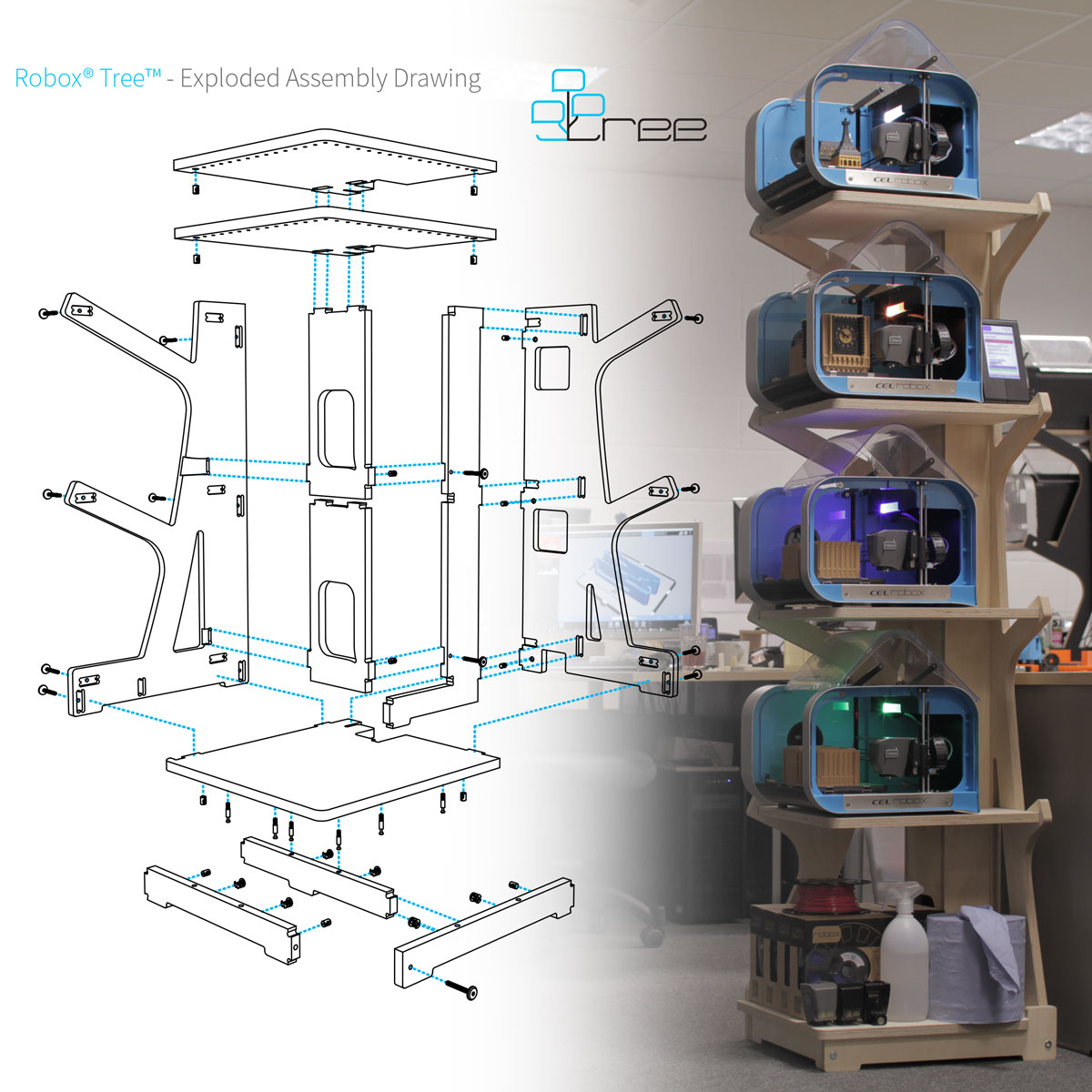

3D PRINTING

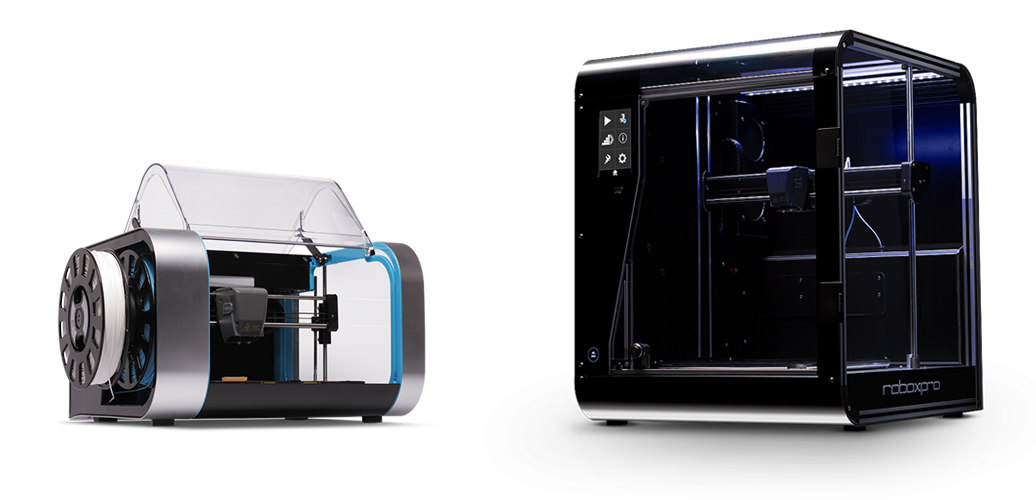

We have a large number of Robox® and RoboxPRO™ 3D printers of our own design which can be used for one-off prototypes right up to short-run manufacturing. Machine specifications can be found below:

Robox®

- Print Technology: Fused Filament Fabrication (FFF/FDM)

- Build Volume: 210 x 150 x 100mm (LxWxH)

- Minimum Layer Height: 50 micron

- Typical Layer Height: 100 / 200 micron

- Part Accuracy: ±0.1mm

- Control Software: Robox® AutoMaker™

- Supported File Formats: .stl or .obj natively, other formats on request – may include a conversion fee.

RoboxPRO™

- Print Technology: Fused Filament Fabrication (FFF/FDM)

- Build Volume: 300 x 210 x 400mm (LxWxH)

- Minimum Layer Height: 50 micron

- Typical Layer Height: 100 / 200 micron

- Part Accuracy: ±0.1mm

- Control Software: Robox® AutoMaker™

- Supported File Formats: .stl or .obj natively, other formats on request – may include a conversion fee.

AVAILABLE MATERIALS FOR 3D PRINTING

- ABS – a strong and impact resistant plastic commonly used in injection moulding.

- PLA – an eco-friendly plastic produced from cornstarch suitable for low cost prototyping

- CO-PET – a co-polyester based plastic which has food contact approval

- PETG – a hard shiny material with excellent light transmission properties

- PolyMax™ PC – an extremely strong and stiff Polycarbonate, ideal for engineering parts

- PA12 – an extremely tough Nylon 12 for hard-wearing components

- HIPS – a low-cost prototyping material with good impact resistance also suitable for support material

- TPU – a very flexible polyurethane material with various options of flexibility and colour for you application

- PolyMide™ CoPA – a blend of Nylon 6 and 6,6 polymers with excellent strength

- PolyWood™ – a wood-like material based on PLA which produces a very smooth surface finish

- PolySupport™ – a specialised breakaway support material for complex geometries

- PVOH – a water-soluble support material allowing for complex geometries

- PA-CF – an extremely stiff carbon fibre reinforced nylon with high strength and excellent surface finish

- PA-GF – an extremely stiff glass fibre reinforced nylon with high strength

- And more! – Get in touch if there’s something not listed…

VINYL/DIE-CUTTING AND PLOTTING

We have an in-house PixMax 720mm (28″) Vinyl Cutter and Plotter which can be used for one-offs or volume production. Hate weeding? We offer cut-only or fully weeded layouts ready for use including application tape. Machine specifications can be found below:

- Maximum Width of Artwork: 720mm

- Maximum Length of Artwork: Unlimited

- Attachments: Roland-style Cutter Blades, Pen Plotter

- Registration: Laser-assisted

- Control Software: SignCut Pro

- Supported File Formats: .dwg, .dxf, .eps, .svg, .ai, .cdr, .pdf, .emf, .bmp, .jpg, .png

AVAILABLE MATERIALS FOR CUTTING

- Self-Adhesive Vinyl including 3M® Comply™ Air-Release – for custom graphics, logos, decals or transfers which can be applied on any surface in a wide range of colours/finishes

- Polymer Films – stylus cut for templates, stencils or jigs/fixtures

- Paper – for custom artwork and print materials

- Plotting – for drawing on a wide variety of sheet materials with any pen/pencil style

- And more! – Get in touch if there’s something not listed…

Contact.

LET’S TALK.

We would love to hear from you about any projects you have planned – you can either contact us directly by phone or use the contact form below to send us an enquiry if you need to attach drawings or supporting information. If your attachment is too large for the contact form, please let us know and we will arrange an alternative method.

CEL CNC Limited

Harbour Place,

Serbert Road,

Portishead,

North Somerset,

BS20 7GF

Mob: +447586 619714

Company No.: 12905005

VAT Reg. No.: GB 359 908 250